Replicating Greatness

What was the challenge?

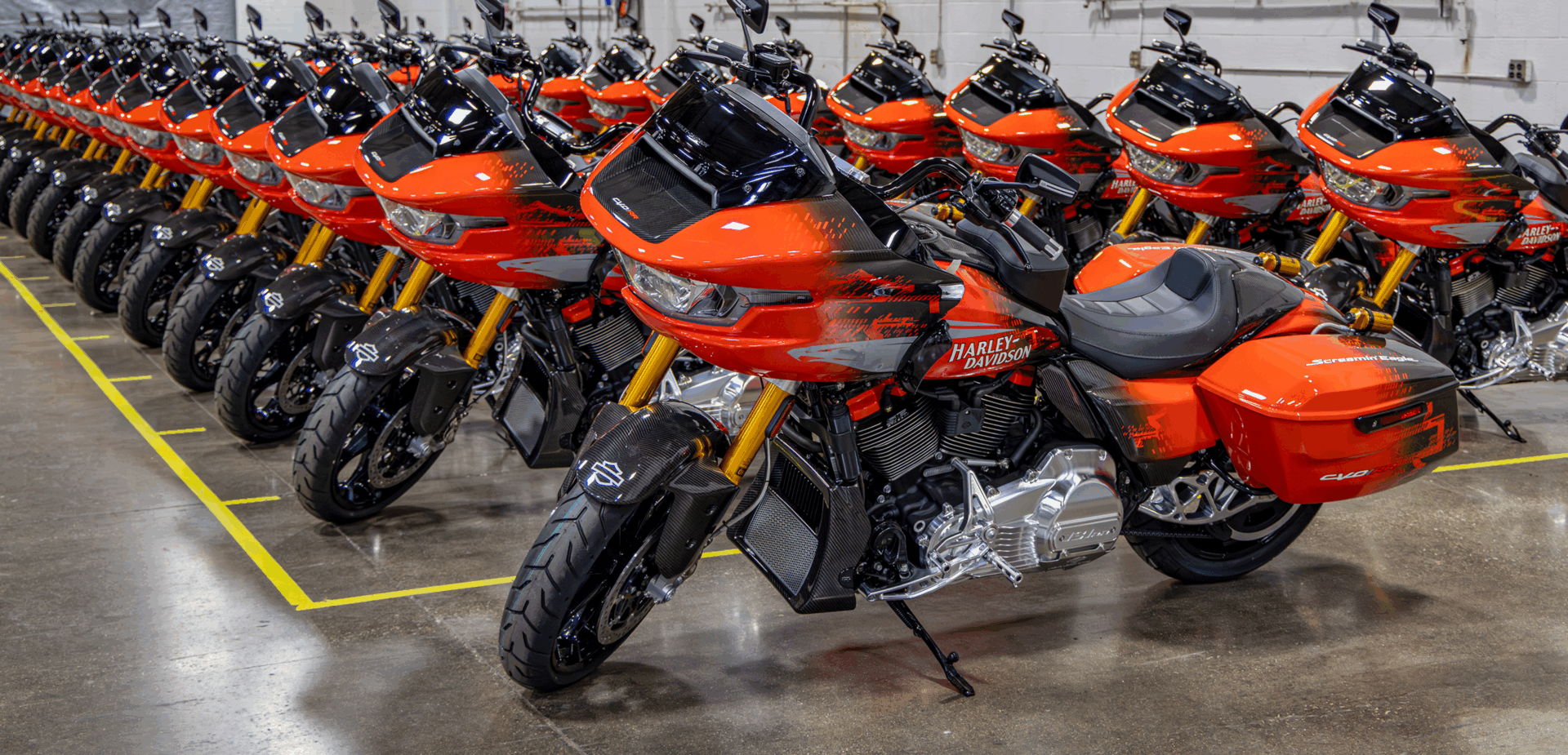

Harley-Davidson had an ambitious goal: create a faithful replica of the popular KOTB race bike with improved durability, precision, and performance for street-legal driving. The original King of the Baggers is a favorite among motorcycle enthusiasts and a thunderous fusion of classic cruiser and race-ready powerhouse. The replica needed to capture the performance build expectations set by the Harley-Davidson Factory Race Team, while ensuring industry-leading material and quality standards.

To meet these standards, the engineering and manufacturing processes required advanced composites and carbon fiber bodywork. These materials were new to Harley-Davidson and had to be appropriately integrated into our collaborative workflows. The bike was also a limited-build project, meaning every component had to be custom-engineered and produced without the familiar scale considerations of high-volume manufacturing.

What did we accomplish?

Replica Component Engineering

Using a combination of digital modeling and precision fabrication, our team reverse-engineered key components of the original KOTB race bike design. We balanced authenticity with performance to retain the look and geometry of the bike while integrating street-legal engineering standards.

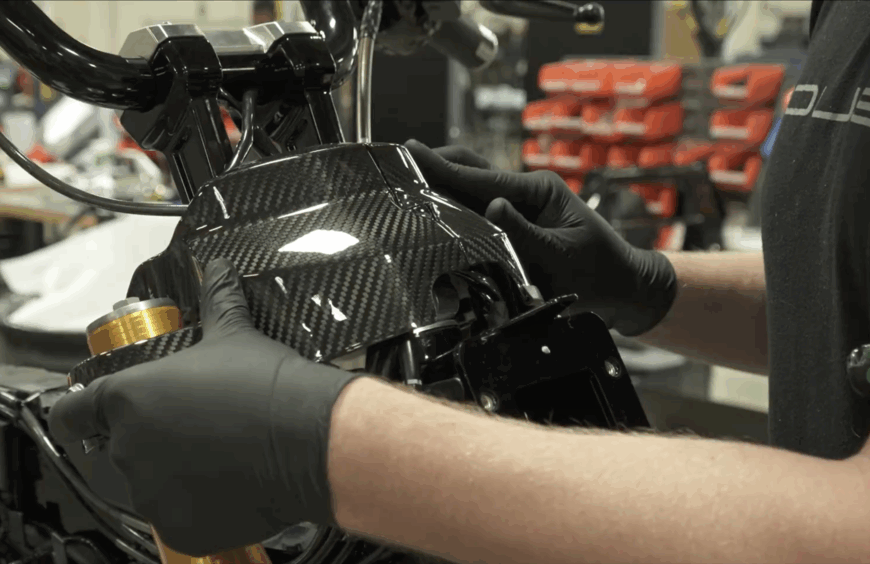

Composite Bodywork Manufacturing

Our Advanced Composites team integrated new materials into the bike design. Alongside Harley-Davidson, we quickly adapted the design with materials like carbon fiber and developed new techniques to create a sleek, lightweight exterior that honors the original race bike.

Low-Volume Assembly

The Roush production team implemented a highly customized workflow to accommodate low-volume assembly. The final result was a meticulously assembled, fully functional, street-legal bike that upholds critical safety standards while meeting the expectations of Harley enthusiasts around the globe.

What services were provided?

Harley-Davidson needed a partner with multiple capabilities under one roof — a partner that could streamline development and manufacturing by handling the entire project. These teams included Design, Vehicle Engineering, Advanced Composites, and Contract Manufacturing.

What is the impact?

The finished street-legal KOTB bike sparked major buzz in the motorcycle community. Among enthusiasts, it has been celebrated as a tribute to street racing events held at iconic venues across the country. The replica delivers a tangible connection to legendary moments on the track, reimagined through modern engineering.

Internally, working alongside Harley-Davidson pushed our boundaries for composite manufacturing, new material integration, and efficient low-volume assembly. We are thrilled to continually expand our manufacturing capabilities — and remain a go-to partner for unique, high-performance projects that drive the future of innovative engineering.

Product photography courtesy of Harley-Davidson.

More Stories

Let’s work together.

Reach Out