Always on the move.

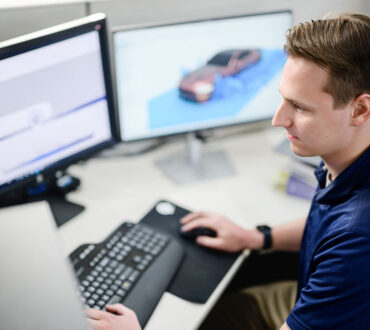

We stand for the top tech in mobility. Roush can handle every element of automotive development.

Work With Us

Our mobility capabilities are literally endless. We design, prototype, test, integrate, manufacture, and assemble across the product development spectrum.

We utilize new materials, structures, models, and simulations.

The latest vehicle programs live at Roush.

Passenger cars across the globe.

Autonomous vehicles.

eMobility.

Commercial vehicles.

Performance vehicles.

Race cars.

Our Stories

We are always driving toward a more mobile, more precise, and more accessible future for global transportation. Having more fun is the goal, too.

Let’s get you on the road to innovation. Together.

Contact UsFrequently Asked Questions

What advancements in eMobility infrastructure can support our development and deployment of EV vehicles?

Advancements such as expanded charging networks, fast-charging stations, and smart grid integration are crucial for supporting EV deployment. Improved battery storage and vehicle-to-grid (V2G) technology enhance energy efficiency and sustainability. These innovations, combined with renewable energy integration, create a scalable eMobility ecosystem. And the outcome of this future ecosystem? Accelerating the shift toward greener transportation through widespread electric vehicle adoption.

How do you handle the testing and validation phase to ensure the battery meets our quality and safety standards?

We implement rigorous testing and validation procedures, including performance assessments, durability tests, and thermal management evaluations. Batteries undergo stress tests to ensure they meet safety, efficiency, and longevity standards. We also conduct real-world simulations and environmental testing to verify reliability under various conditions. This comprehensive approach ensures the battery meets our stringent quality and safety benchmarks before deployment.

Are driverless cars safe?

Driverless cars are designed with advanced safety features, including sensors, cameras, and AI systems to minimize human error — the leading cause of accidents. However, their safety depends on factors like technological reliability, infrastructure, and regulatory oversight. While testing shows promise, challenges like handling complex driving environments are still relevant. Ongoing advancements in mobility technology aim to make driverless cars increasingly safer over time.

Still have questions? Connect with our team to learn more.