Let’s test.

The bar for compliance is always high. At Roush, our standard is higher. That’s why we test across a broad spectrum of crucial fields. Plus, we love testing outside of a controlled setting. We actively seek real environments in the real world — so we can solve real challenges.

NVH and Dynamometer Testing

Discover the data behind the power. Our dynamometer testing capabilities lead the industry with powertrain testing and development resources for the automotive, industrial, marine, defense, motorsport, and aerospace industries. And we have 50 test cells to prove it.

On-Road Vehicle and Advanced Durability Testing

Our passion for testing is unconditional. Whether it’s icy terrains or winding mountain passes, we seek out extreme conditions to perform real-world testing. Cutting-edge sensors collect vehicle information, including speed, acceleration, handling, and brake testing characteristics. Roush’s Six Degree of Freedom Spindle Coupled Road Simulator also stands out in the industry and rigorously tests full vehicles and vehicle components.

Emissions Testing

The Roush emissions testing laboratory is built to clear the air. Meet a team that upholds CARB Certification and services that are EPA compliant, ARB compliant, and surpass all CAP200 testing requirements. We perform emissions certification support across a diverse variety of markets for R&D, certifications, and in-use vehicle testing.

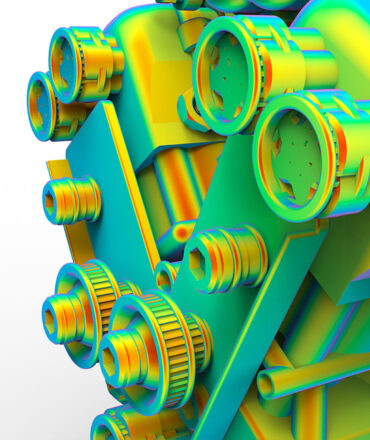

FEA (Finite Element Analysis)

FEA is prediction made purposeful. We create FEA models to validate and perform structural and torsional analysis of components and assemblies, which greatly reduces the cost and time required for product development activities.

Let’s work together.

Connect With Us