Flying High in Air Mobility

Flying High in Air Mobility

Ready for virtually any challenge.

Topics:

What is the role of CAE in Product Development?

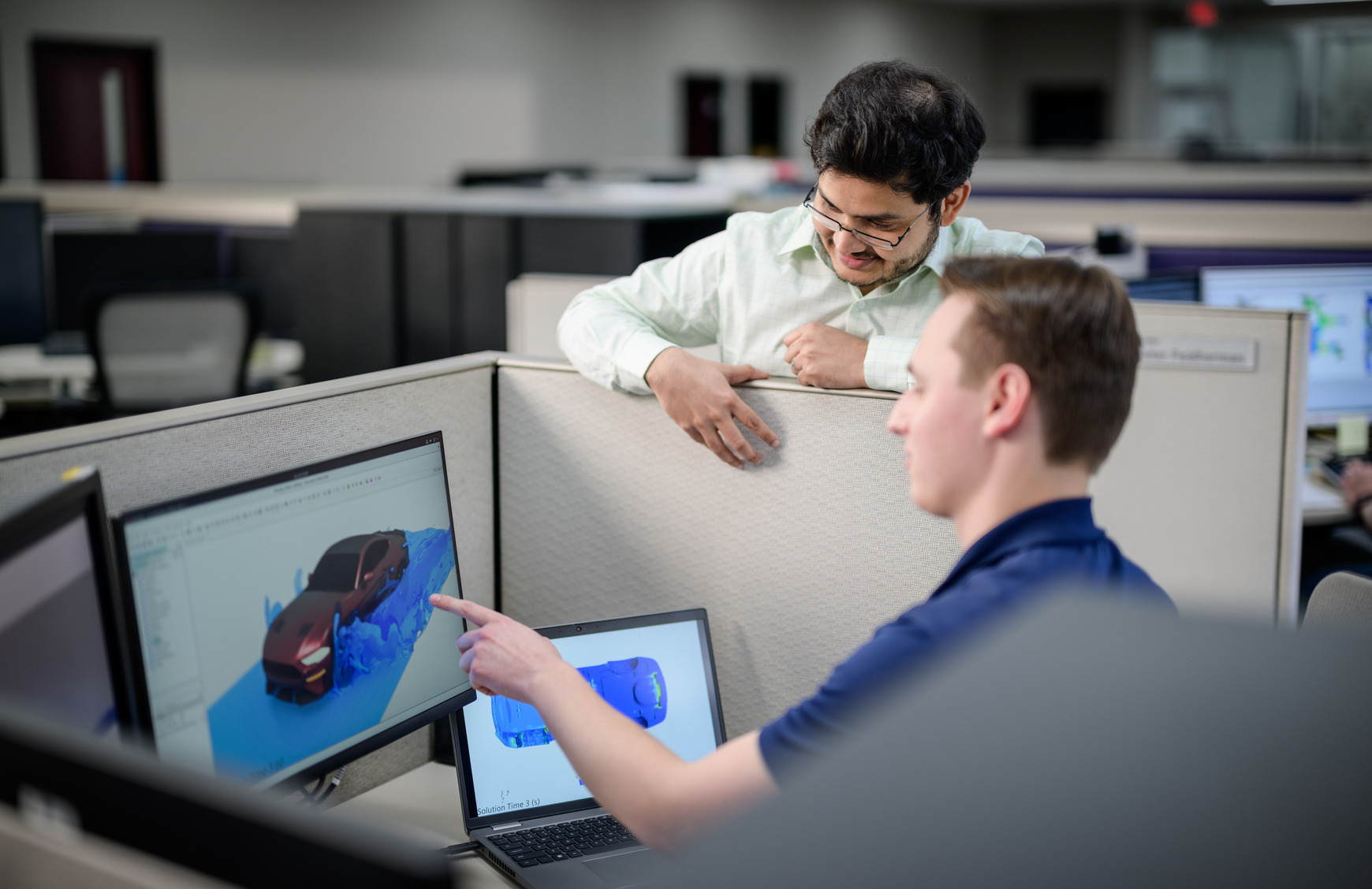

Computer Aided Engineering (CAE) is the use of computer software to simulate, predict, and improve product performance at any stage of the product development process. At Roush, using CAE technology is important because it provides valuable insight into the performance of a product without the need for costly and time-consuming physical testing for our customers. In fact, an entire assembly can be simulated virtually before even a single physical part is ever created.

CAE provides valuable insight into the performance of a product without the need for physical testing.

How is FEA used to provide customer solutions?

Finite Element Analysis (FEA) is a valuable tool that the CAE team uses to solve a wide variety of structural analysis problems. FEA is a mathematical tool that can be applied to a number of engineering situations to simulate complex problems that are not easily or accurately captured by hand calculations. It is critical in providing confidence in the designs operating under complex situations without creating an expensive physical prototype.

How does the CAE team at Roush benefit customers across a broad range of industries?

The use of CAE technology by our dedicated team makes a positive impact for customers in three key areas.

Fully integrated services

Roush’s CAE team can integrate with any other department in the company to arrive at solutions that work for end customers in a variety of industries.

Ability to quickly adapt

Thanks to the diversity and size of the CAE team at Roush, resources can be scaled quickly for specific projects.

Development for specific industries

The CAE team at Roush is always developing internal tools to improve efficiency and capabilities for specific industries. Click here to see all industries we serve.

What types of industries and projects do customers bring to Roush’s CAE team?

CAE technology can be implemented into any phase of a product’s lifecycle, so there are limitless possibilities for the Roush team. Industries served with Roush’s CAE technology include mobility, aerospace, entertainment, defense, and beyond. CAE services at Roush are nearly endless, too. Capabilities include durability analysis, NVH (noise, vibration, and harshness), crash and safety, CFD, multibody dynamics, composite analysis, manufacturing process analysis, third-party design/analysis audits, root-cause analysis, testing, and material characterization. Click here to see all capabilities at Roush Industries.

CAE technology can be implemented into any phase of a product’s lifecycle, so there are limitless possibilities for the Roush team.

How does the CAE team at Roush make an impact?

The use of CAE at Roush has been important for customers of every size — from the smallest start-ups to large OEMs with an international presence. Recently, an established OEM from the West Coast approached Roush Industries with a serious NVH engineering problem. The CAE team quickly formulated a strategy to use state-of-the-art testing facilities and CAE simulation to represent the physics of the problem, arrive at solutions, create prototype parts, and demonstrate the anticipated benefit. And the best part? Thanks to the creativity, responsiveness, and determination of the team at Roush, it all got done in a few months.

Related Blog Posts

Flying High in Air Mobility

Flying High in Air Mobility

Contract Manufacturing Brings the Remarkable to Life

Contract Manufacturing Brings the Remarkable to Life

Tackling a Startup’s Challenges With Solutions That Are “Just Right”

Tackling a Startup’s Challenges With Solutions That Are “Just Right”